The group owns MTI inertia friction welding machine, which has good alignment, ensures the straightness quality of drill pipe / weighted drill pipe, strictly controls the weld loss within + / - 10%, and ensures the accuracy of the final length. Stable welding parameters and welding zone heat treatment ensure the welding performance. The advanced technology of high power current collecting coil and narrowing the heat affected zone, and the heat treatment process of internal and external coolin

Drill Pipe Body Performance Parameters

The integral heavy-duty drill pipe is made of AISI4145H alloy steel, in accordance with API specifications and SY, T5146 standards. The material is integrally forged by a precision forging machine, and then subjected to integral heat treatment in a heat treatment furnace. Wear-resistant belts are spray-welded on the joints at both ends and the middle section. 100XT, 300XT wear-resistant materials authorized by American Encore can be spray-welded. The threads can be cold rolled, copper plated or phosphated, and double-shoulder threads and special threads of other specifications can be processed.

Technical Parameter:

Specification outer diameter | Nominal weight | Calculate weight | Steel grade | wall thickness | Thickened type | ||||

In | mm | ib/ft | kg/m | in | mm | ||||

2 3/8 | 60.3 | 6.65 | 6.26 | 9.32 | E,X,G,S | 0.280 | 7.11 | EU | |

2 7/8 | 73.0 | 10.4 | 9.72 | 14.48 | E,X,G,S | 0.362 | 9.19 | EU、IU | |

3 1/2 | 88.9 | 9.50 | 8.81 | 13.12 | E | 0.254 | 6.45 | EU | |

3 1/2 | 88.9 | 13.30 | 12.31 | 18.34 | E,X,G,S | 0.368 | 9.35 | EU | |

3 1/2 | 88.9 | 15.50 | 14.63 | 21.79 | E,X,G,S | 0.449 | 11.40 | EU | |

4 | 101.6 | 14.00 | 12.93 | 19.26 | E,X,G,S | 0.330 | 8.38 | EU、IU | |

4 1/2 | 114.3 | 13.75 | 12.24 | 18.23 | E | 0.271 | 8.38 | IU | |

4 1/2 | 114.3 | 16.60 | 14.98 | 22.31 | E,X,G,S | 0.337 | 8.56 | EU、IEU | |

4 1/2 | 114.3 | 20.00 | 18.69 | 27.84 | E,X,G,S | 0.430 | 10.92 | EU、IEU | |

5 | 127.0 | 19.50 | 17.93 | 26.71 | E,X,G,S | 0.362 | 9.19 | IEU | |

5 | 127.0 | 25.60 | 24.03 | 35.79 | E,X,G,S | 0.500 | 12.70 | EU、IEU | |

5 1/2 | 139.7 | 21.90 | 19.81 | 29.51 | E,X,G,S | 0.361 | 9.17 | IEU | |

5 1/2 | 139.7 | 24.70 | 22.54 | 33.57 | E,X,G,S | 0.415 | 10.54 | IEU | |

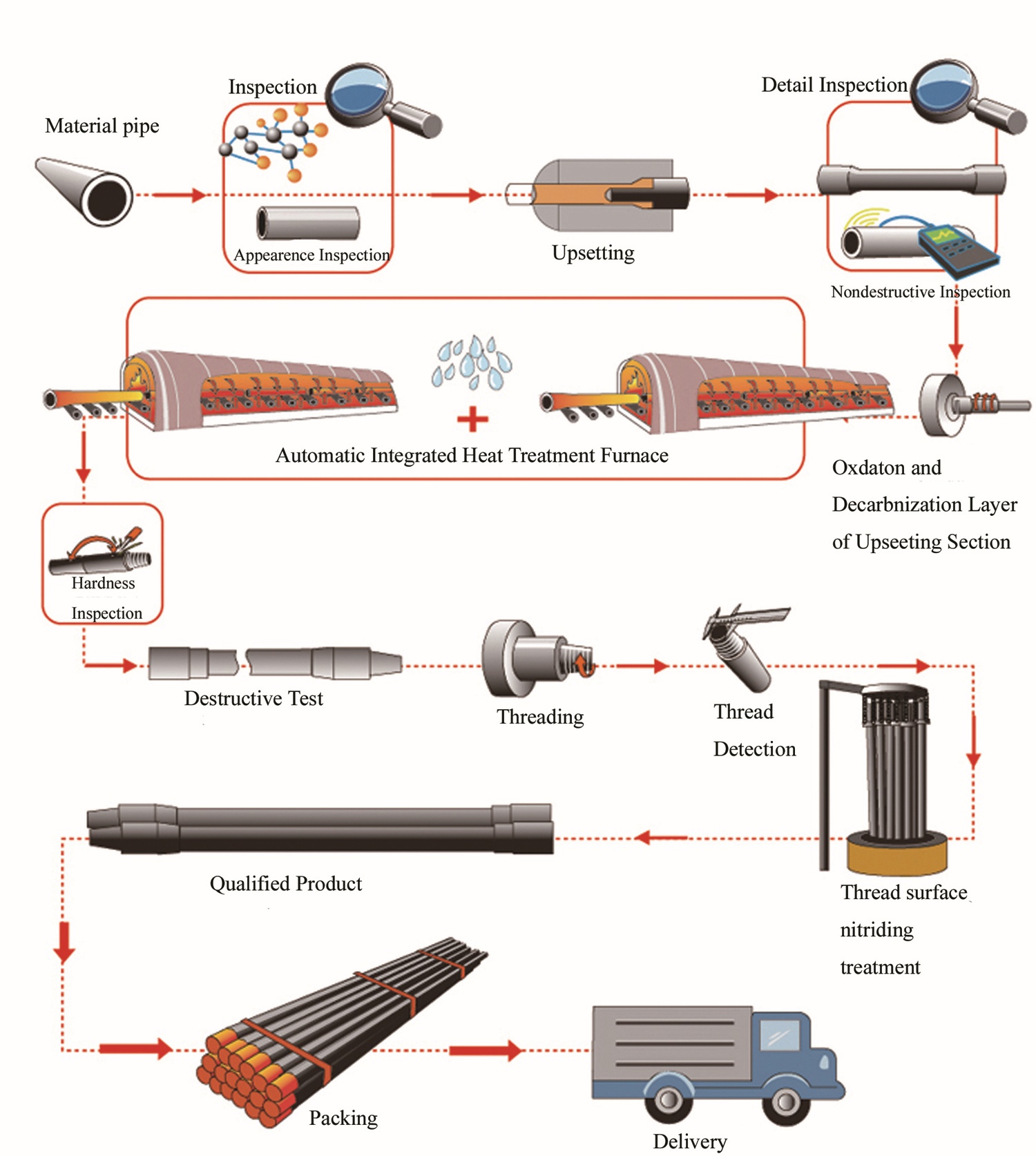

Process Flow Diagram

Contact: Andy

Phone: +86 13002925309

Tel: +86 13002925309

Email: admin@taihedrillingtools.cn

Add: Room 1311, Building T8, China Resources Land Mixc, Sanqiao, Xi'an, Shaanxi

We chat